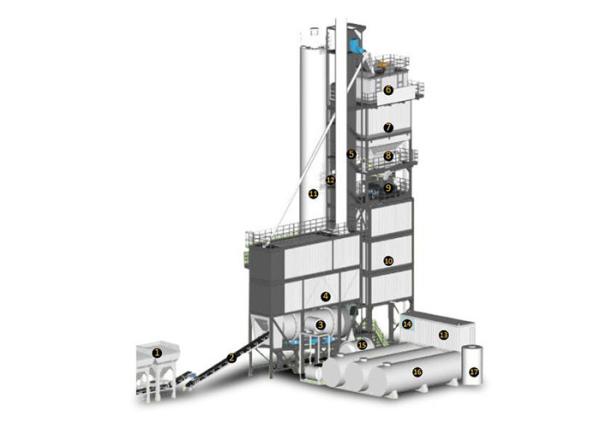

| Configuration Table (Standard) | |

| Cold Feed | QTY |

"The isolated compartments of the cold aggregate hopper,

idth of each bin:3250mm,Height of each bin: 3000mm,Capacity:

6m³/each; | 4 |

| With protection grids on the compartments and repair platform &

railings | 1 |

| Vibrating motor for the sand hopper. | 1 |

| Variable speed discharge belt,Capacity:0~50t/h each | 4 |

| Shaft-mounted reducer motor driven horizontal collecting belt,

Capacity:130t/h | 1 |

| Shaft-mounted reducer driven by rapid electrical feed

conveyor,Capacity: 130t/h | |

| With head cleaner and end cleaner of the belts | 1 |

| Oil Burner | |

| Bubble atomization,light/heavy oil,1000 kg/h | 1 |

| Equipped with automatic flame failure protection devices for

emergency | 1 |

| Dryer capacity 120t/h,moisture 3% | 1 |

| Gas tank:0.6m³ | 1 |

| Drum Dryer | |

| Dimension:φ1800×7000mm | 1 |

| Driven by friction-driven variable speed motor | 4 |

| Rock wool isolated, stainless steel covered. | 1 |

| Temperature sensor with thermocouple | 1 |

| Bitumen heating system (Conduction Oil Heating) | |

| One burner (400,000kcal/h) for diathermia oil | 1 |

| 30t bitumen tank | 1 |

| All bitumen pipe and diathermia oil pipe | 1 |

| Bitumen recycling system, pumps, heat valves, pipes | 1 |

| Bitumen discharge pool | 1 |

| Pneumatic System | |

| Screw-type air compressor | 1 |

| Taiwan Airtac pneumatic components. | 1 |

| The Mixer | |

| Hot aggregates elevator,motor driven,capacity 130t/h | 1 |

| Filler elevator,motor driven,capacity 20t/h | 1 |

| Linear vibration, 4 kinds of aggregates, 4 deck,double

electro-vibrators;Sealed, dust proof., negative-pressure | 1 |

| 4 aggregate hoppers and 1 recovery filler temporary bin;Effective

capacity of total aggregate bin is 25 m³ | 1 |

| Level indicator. | 4 |

| Weighing system: Aggregate:1500kg/batch; Filler:200kg/batch;

Bitumen:200kg/batch; | 1 |

| Mixer:1500kg/batch,Mixing period:45s | 1 |

| Support and ladder and platform. | 1 |

| The artificial powder screw conveyor | 1 |

| Control System | |

| Control room 5m×2.2m×2.4m(L×W×H) | 1 |

| Industrial control systems, office-based console, control cabinet,

all computer animation interface | 1 |

| 17' LCD significant,Siemens Inverter | 1 |

| Omron PLC modules | 1 |

| Additional supply | |

| Accessories | 1 |

| Tools | 1 |

| Configuration Table (Optional) | |

| Finished storage hopper(30t Integrated bin) | |

| Capacity: 30 tons,50mm thick insulation materials | 1 |

| Discharge door electrical heating | 1 |

| Finished storage hopper full alarm display | 1 |

| New Filler Supply System | |

| Linear drums filler tank, capacity: 40m³, vertical | 1 |

| Level indicators (upper and lower) | 2 |

| Filler screw conveyor | 1 |

| Pneumatic Vibrator | 1 |

| Double flange butterfly valve of powder | 1 |

| Recycled Filler Supply System | |

| Linear drums recycled filler tank, capacity: 30m³, vertical | 1 |

| Level indicators (upper and lower) | 2 |

| Recycled filler screw conveyor | 1 |

| Impeller feeder | 1 |

| Pneumatic Vibrator | 1 |

| Double flange butterfly valve of powder | 1 |

| Bag House Dust Collecting System | |

| Gravity filter (level one) , Bag house (level two) | 1 |

| Bag house ,Filtering area:448m²,Efficiency:99%,NOMEX | 1 |

| One vent | 1 |

| Exhaust Gas Temperature Measurement Sensors | 1 |

| Cold wind valve | 1 |

| Diesel Supply System | |

| Diesel tank: 10m³ | 1 |

| Valves, oil pipes and so on. | 1 |